Why Is Sugar Found in Many Processed Foods?

Sugar in processed foods is all around us, which might make you ask, why? What is the purpose of so much sugar, if any? Health-conscious diets are on the rise and sugar is getting a bad rap, but it is important to understand the role and different types of sugar to form an opinion. We will dive into the functions of sugar in processed foods, as well as the types of sugars and sweeteners essential for the food and beverage industry.

What is Processed Sugar? What Are it's Functions in Food?

1. Preservation of Product

Sugar in baked goods prevents them from drying out and extends the shelf life by prolonging when they turn stale. Sugar is also hygroscopic, which reduces water activity in food by the sugar absorbing water from the surrounding environment, further extending the product’s life.

2. Taste

The reality is the most common foods manufacturers produce would not be popular without sugar’s sweetness. Many products would be nothing without their sugar content, the entire flavor profile is structured on the aroma, and other flavors play off the sweetness.

3. Color

Caramelization is a method used in various products such as sauces, candies, jams, loaves of bread, and even dessert wine. This process happens from the formation of multiple colors coming together through ingredients and heating the sugar to at least 320 °F, which is evident when the sugar changes to pale caramel brown. This can only be achieved if sugar is in the product.

4. Bulk / Texture

The texture that sugar adds all depends on the product. This can range from the light, airiness of ice cream compared to hard candies. Sugar is a means to mold your product into not only the desired taste but texture as well. The results are infinite when using sugar substances to alter the consistency of food. Depending on the sugar or sweetener, it can add bulk in terms of caloric content; the simplest way to achieve this is using fructose.

5. Fermentation

Sugar is a typical substance used in the process of fermentation. Many foods require fermenting, such as yogurt, sour cream, wine, cheese, bread, beer, etc. The process dramatically quickens when sugar is added. In the absence of oxygen, the process can create energy by oxidizing the sugar.

Types of Sugars and Sweeteners

Flavoring Agents

Flavoring agents are additives used in foods to add new flavors, complement the existing, or replenish lost flavors that became weakened during processing. Flavoring agents are the most extensive group of food additives in the industry, with over 1200 different flavoring agents used to simulate flavors. Some examples include:

- Alcohols

- Esters

- Aldehydes

- Ketones

- Protein hydrolysates

- MSG

Gels

Gelling agents in food are processed throughout the world. The formation of gelatin all depends on the temperature, pH, concentration of the gelling agent, and other factors. The process includes the gel-forming agents, which dissolve in a liquid to form a jelly-like mixture. Gelling agents also may be used to stabilize or thicken a product due to the weak cohesive properties.

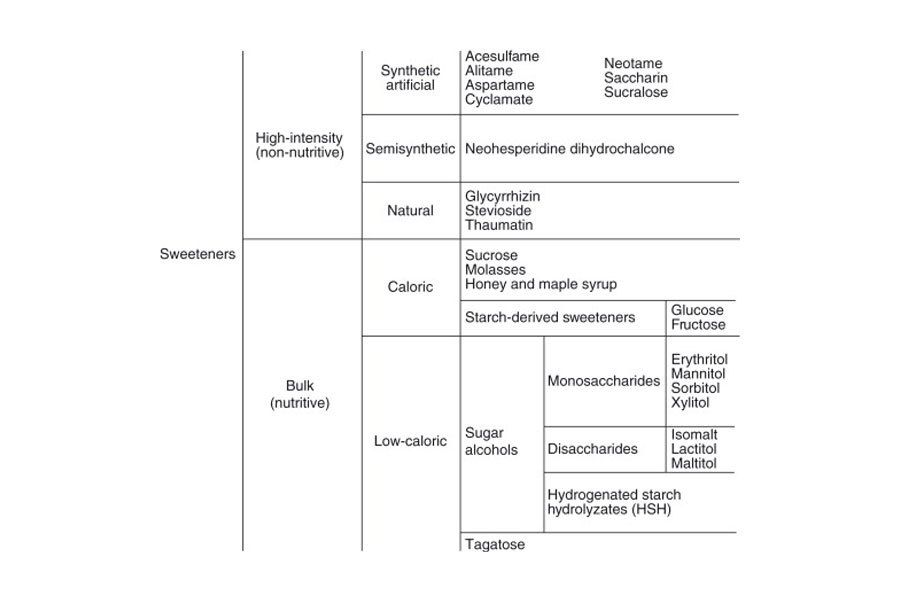

Sweetening Agents

This food additive, intuitively, is used to give products a sweet taste. This may come as a surprise, but foods that naturally have sweetening properties are not in this category as an additive, such as honey and sugar. This category is divided into high intensity or bulk, both serving essential purposes in products. The high-intensity sweeteners add virtually no calories or “bulk” to foods, compared to bulk sweeteners add calories, which translates into energy from the product.

Fructose

This is the simplest carbohydrate, a direct way to get “bulk” or calories in a product. The industrialization of farming with the food industry established easier accessibility to this product. Adding it to foods via extraction from corn has made the product available widespread and no longer means we need a surplus of fruits, vegetables, and grains to get enough in the western diet. There is now an abundance fortified in processed foods due to the low cost and high sweetness.

Sucrose

Typically extracted from sugar cane or sugar beet, this is the commonly known table sugar. Sucrose has been incorporated into the human diet throughout all of history and is essential for proper nutrition. The extensive process to gather sucrose includes clarification, collecting juice from the plant, breaking down components, and boiling the liquid to collect the juice and liquid. The next steps are putting “seed sugar crystals” or completed sugar, so the substance crystallizes and grows to the other crystals’ size. A machine sifts through the elements sifting out the sugar and collecting the molasses. If processed from sugarcane, the final step is bleaching the crystals white by putting them through natural carbon.

Glucose

This sugar type’s primary purpose is to improve the taste and the shelf life of the product, which is highly versatile in its usability. In processed foods, it is commonly extracted from cornstarch, forming dextrose. Glucose is essential for everyone because once ingested; your body carries the glucose to every organ to make energy. Glucose can come in many forms and is the body’s preferred carb-based energy source.

Working with Indiana Sugars

Need bulk sugars & sweeteners your business? We supply high-quality, bulk ingredients at affordable prices. Indiana Sugars online allows us to provide you with a 24/7 marketplace for your convenience. Contact our team with any questions you may have and let us know how we can help you.

We look forward to hearing from you!